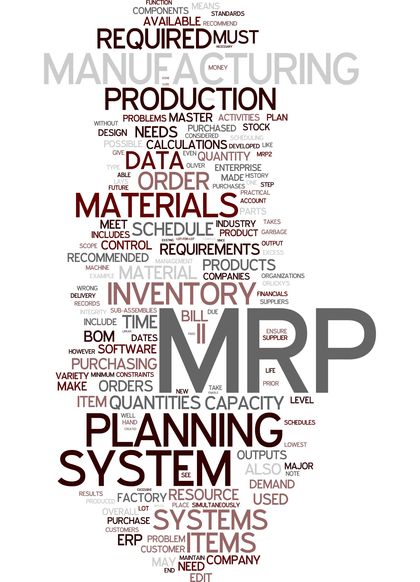

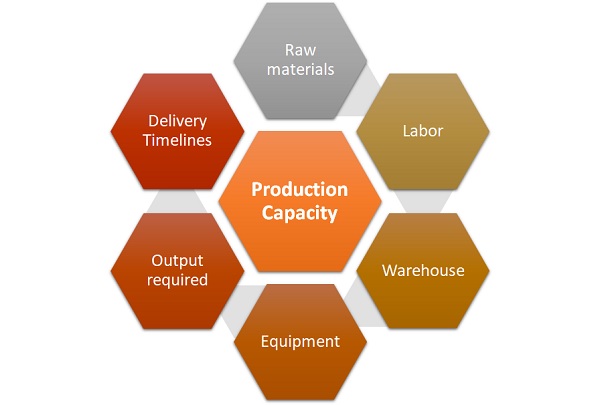

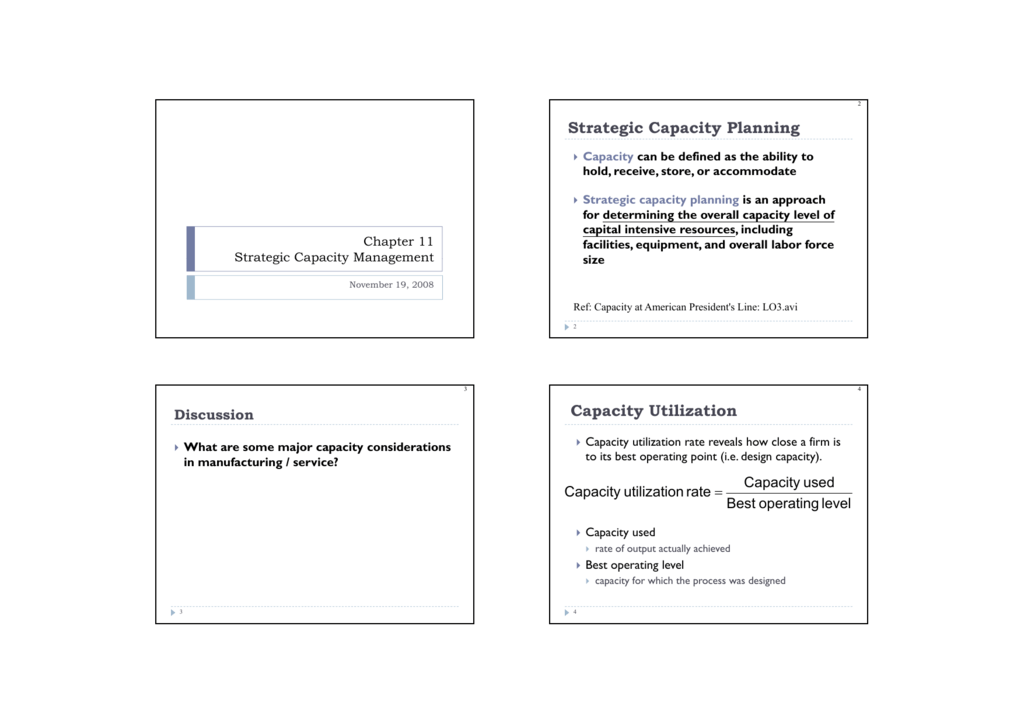

Provide the purpose of the capacity plan For example Capacity planning is an important part of infrastructure and deployment planning A capacity plan supports the goal of optimum, and cost effective, provisioning of organizational resources and services by matching them to businessCapacity is often measured in hours available to be worked by employees And in this context, "planning" is the act of scheduling employee hours against a fixed or expected amount of work Example A company has 10 employees Each employee works 40 hours per week 40 xCapacity can be defined as The maximum output that a business can produce in a given period with the available resources Capacity is usually measured in production units (eg 1,000 cars per month) Productive capacity can change eg when a machine is having maintenance, capacity

The 21 Guide To Product Roadmaps

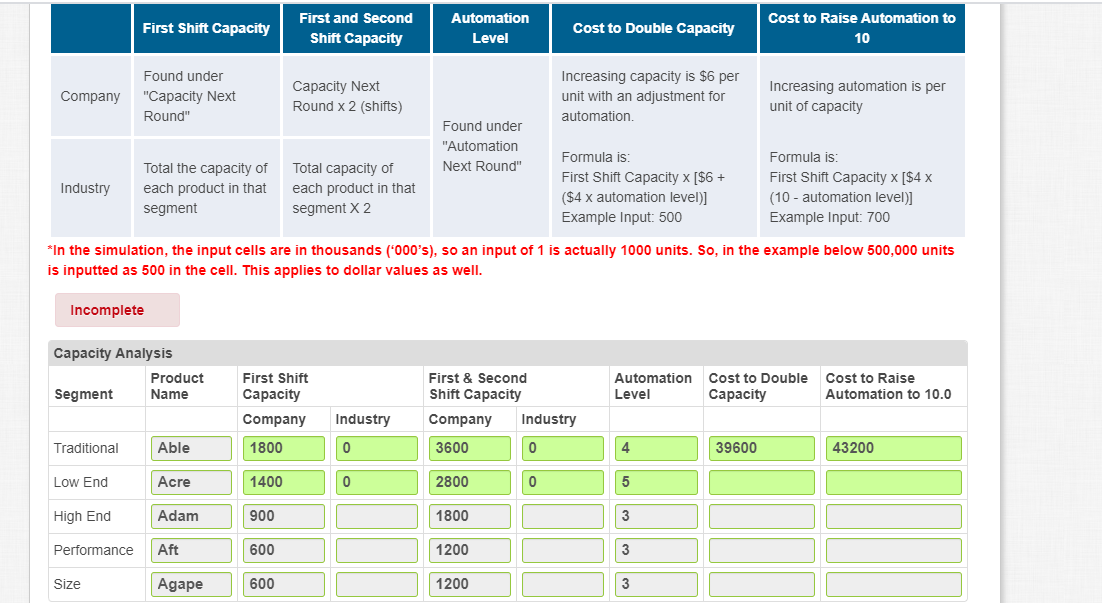

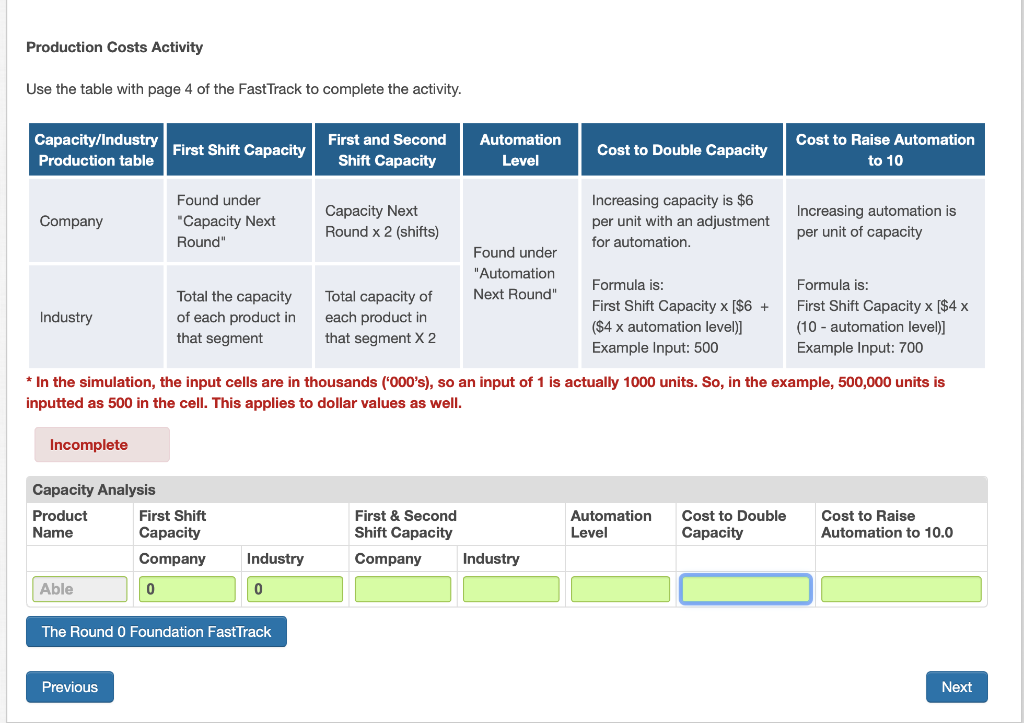

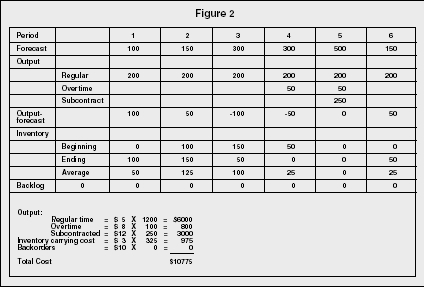

Level capacity example company

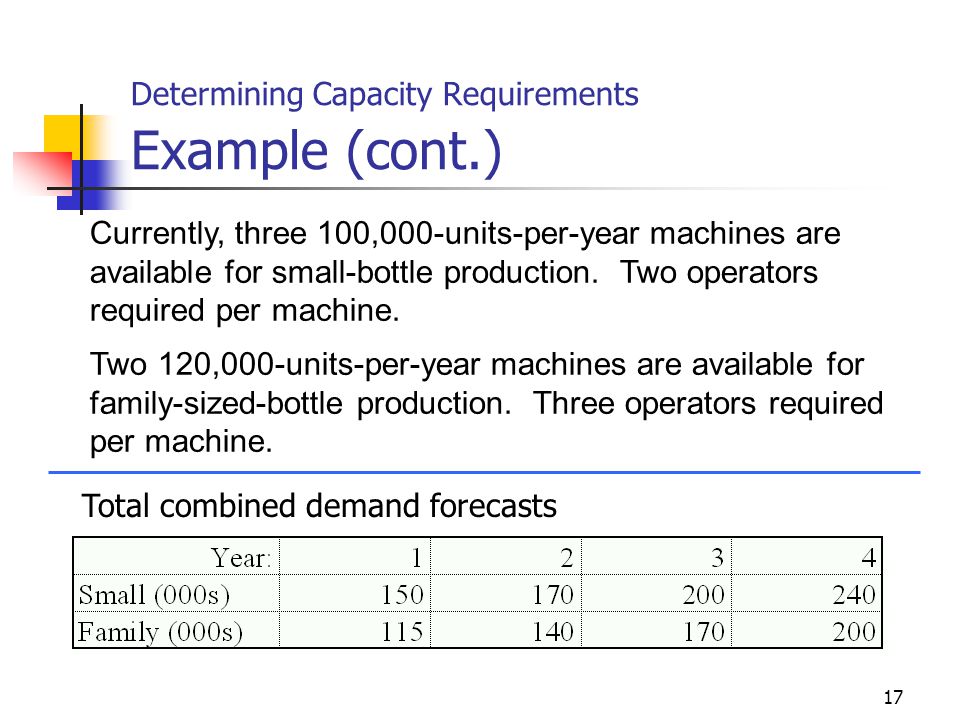

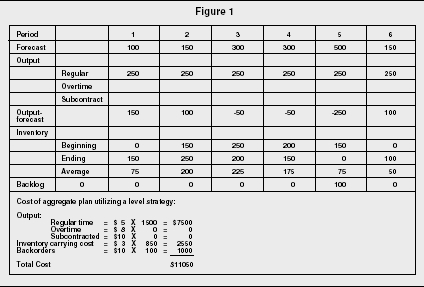

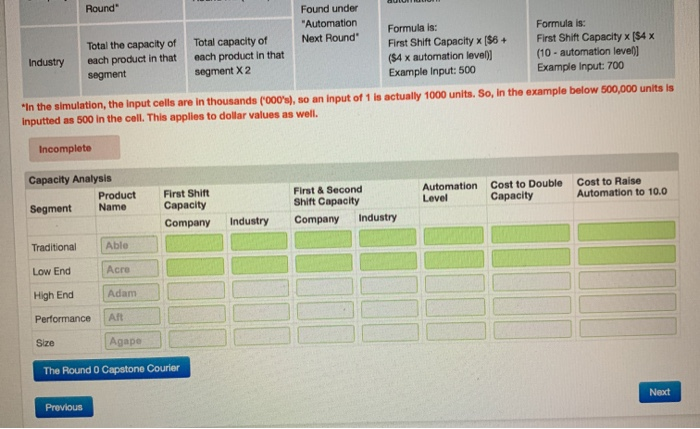

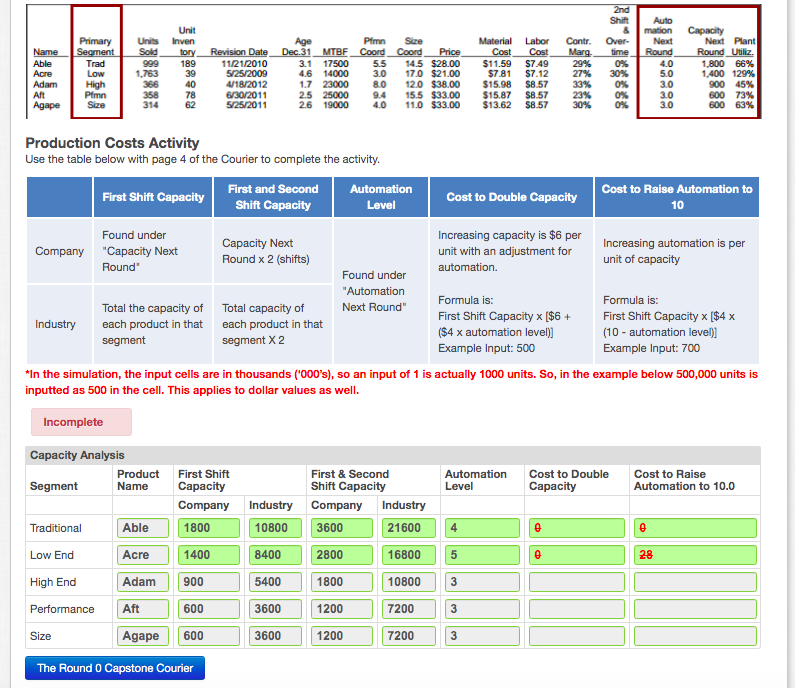

Level capacity example company-For example Production Line= Traditional Shift Capacity ('000) Automation Level Cost to Double Capacity Cost to Raise Automation to 100 Company Industry(6X) 1 2 Multiply the 1 st shift Capacity for your Company & Industry by 2 and place the result in the "1 st & 2 nd Shift Capacity" columns– Capacity has a cost – Lead times are greater than zero Aggregate planning – Is the process by which a company determines levels of capacity, production, subcontracting, inventory, stockouts, and pricing over a specified time horizon – goal is to maximize profit Or, if demand is

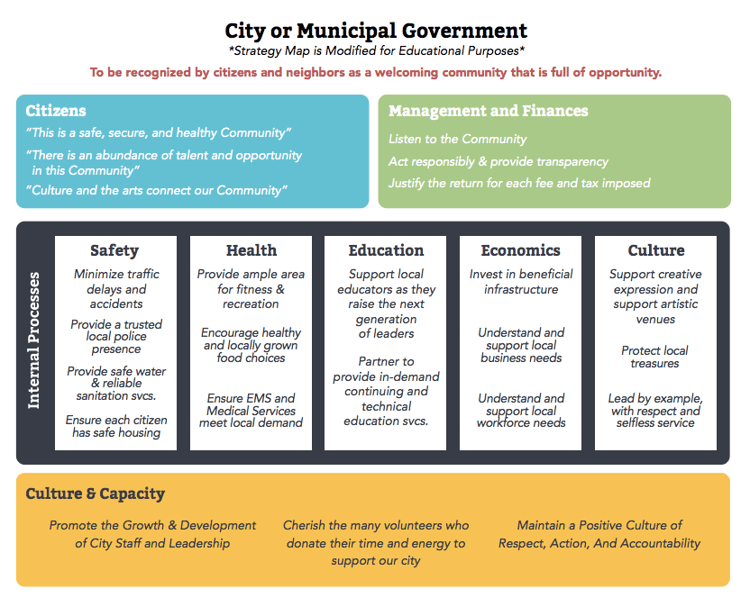

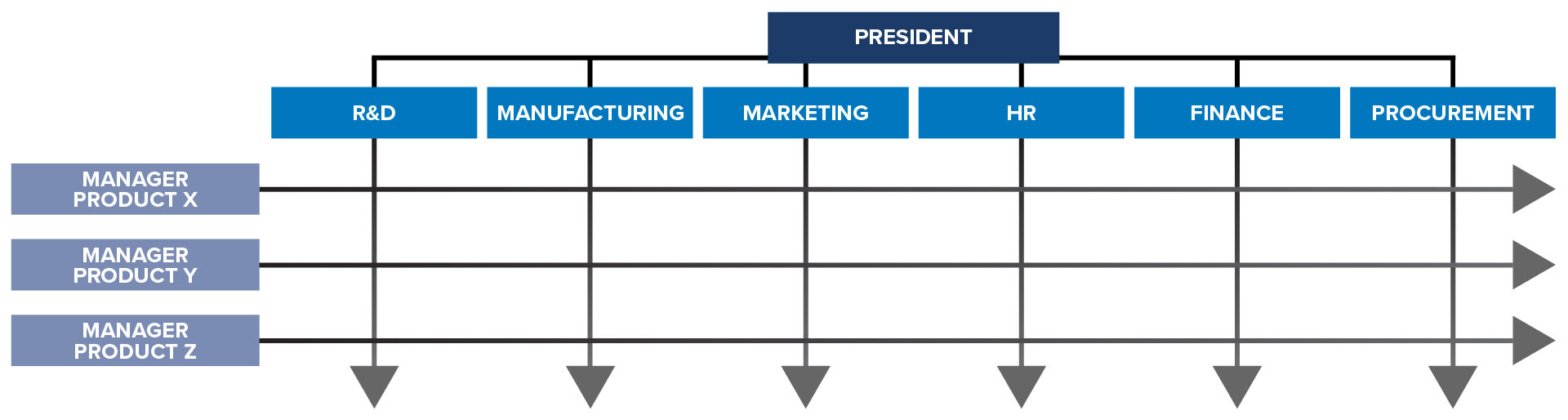

Common Types Of Corporate Strategies Boundless Management

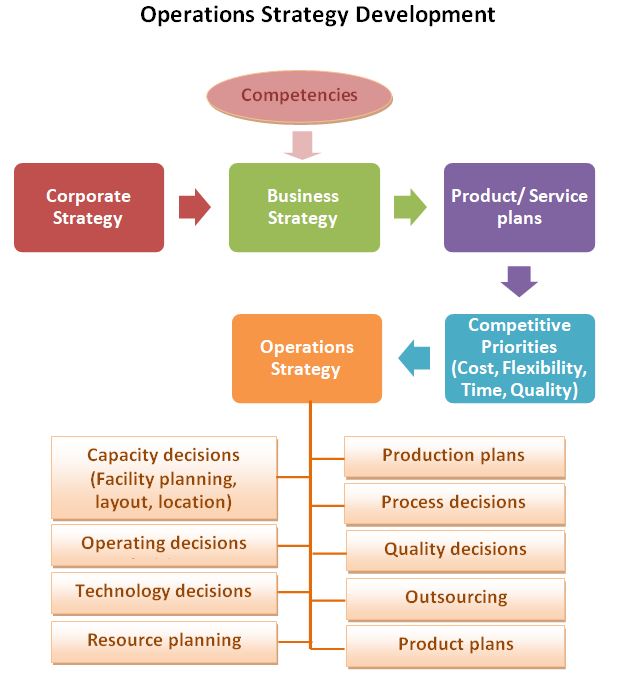

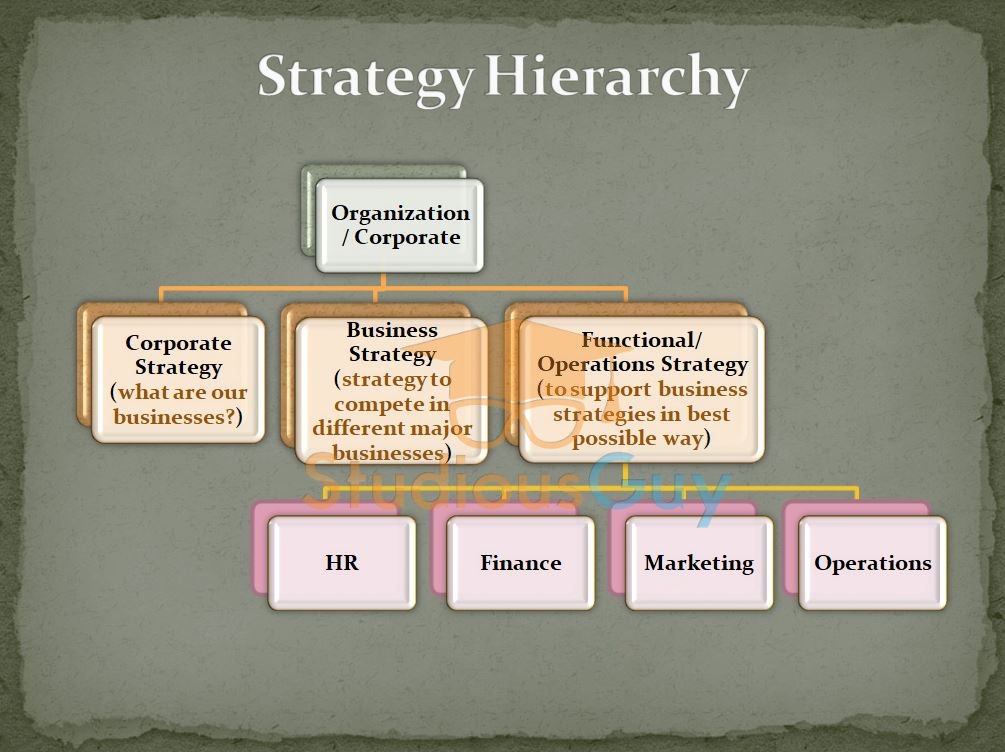

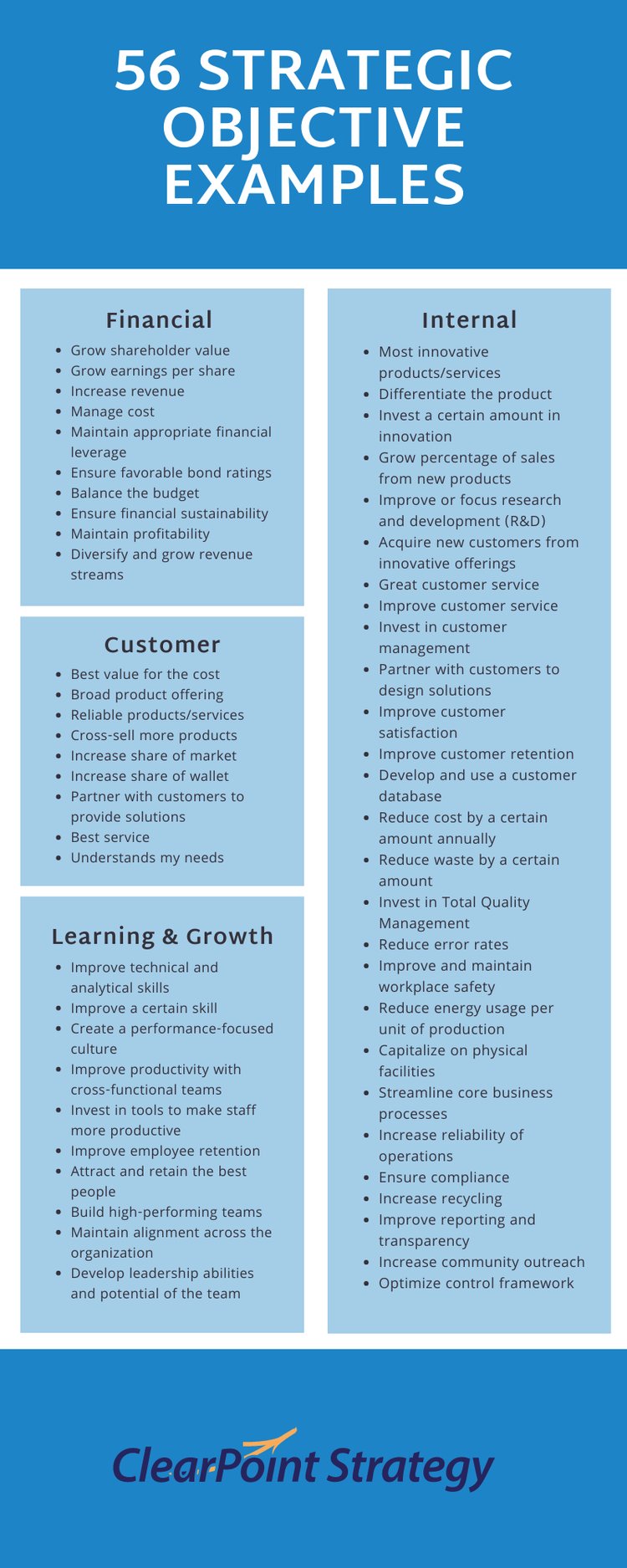

A typical example of this is a situation where your firm has just won a big contract and it involves an extensive level of work with varying skills you might not have in your company A great thing about capacity planning is that it allows you to identify any problem early The use of a chase strategy requires that a company have the ability to readily change its output level, which means that it must be able to readily change its capacity In some industries where labor is the major determinant of capacity, and where additional labor is readily available, such changes may be feasibleThe subject business strategy is easier to understand—to make coherent—by viewing each one as part of a strategic framework The strategic framework is a hierarchy At the top sits the firm's overall (or generic) business strategy Here, the aim is the highestlevel business objective earn, sustain, and grow profits

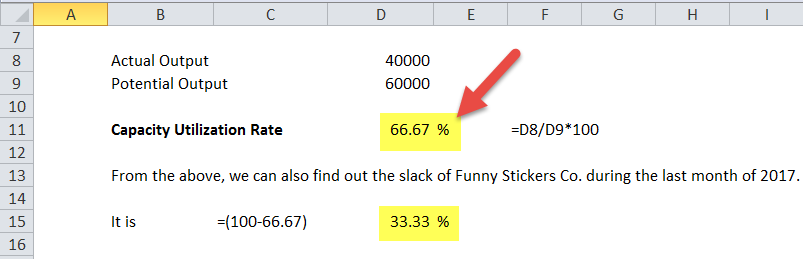

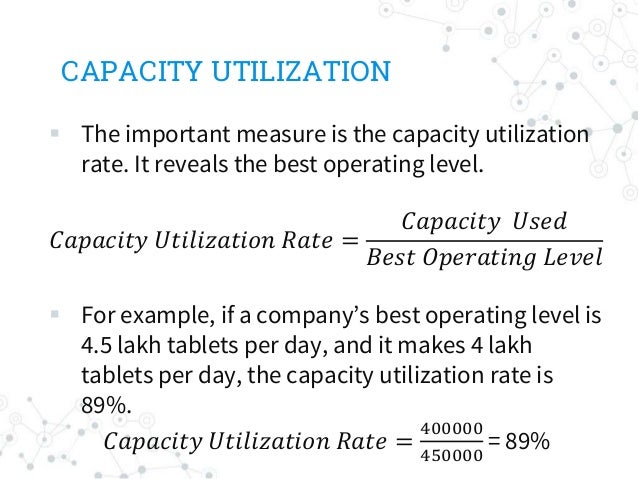

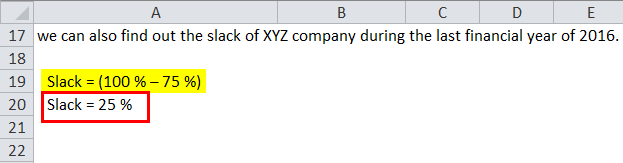

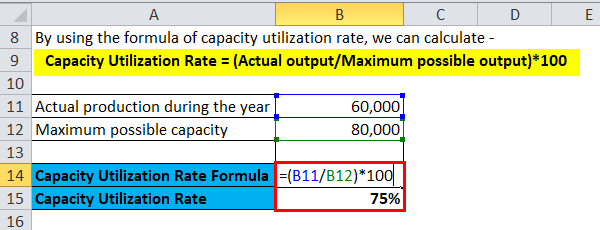

AQA, Edexcel, OCR, IB Capacity utilisation is a measure of the extent to which the productive capacity of a business is being used It can be defined as The percentage of total capacity that is actually being achieved in a given period Revision Video Calculating Capacity Utilisation Revision Video Capacity Management1 The utilization of operational resources throughout the year 2 Efficient level of production can be maintained 3 Decreases the marginal cost The disadvantages of the level capacity strategy include 1 If there is any change in the demand of the customer there is a risk of obsolescenceFor example, a business culture that appreciates and supports continued learning has a higher absorptive capacity than other business cultures that do not support individual learning and development To further clarify concepts related to the absorptive capacity theory, Wheeler 8 introduced an application derived from the dynamic capability

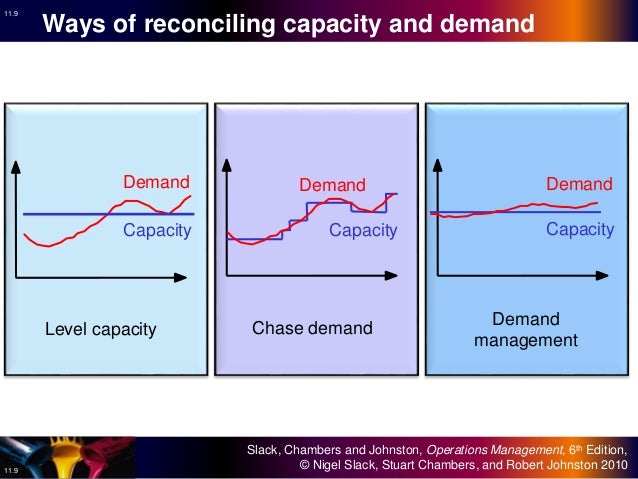

We will write a custom Essay on Mcdonald's Company Capacity and Forecasting specifically for you for only $1605 $11/page 812 certified writers online Learn More One capacity issue that applies to McDonald's involves demand The demand for fast food items peaks at certain times of the day Consequently, it is quite difficult for theCapacity is the maximum level of output that a company can sustain to make a product or provide a service Planning for capacity requires management toIn this rundown of the juggling feat service managers perform, the author discusses the two basic strategies—"chase demand" and "level capacity"—available to most service companies

How To Calculate Production Capacity Of A Factory

The 3 Different Levels Of Management Sprigghr

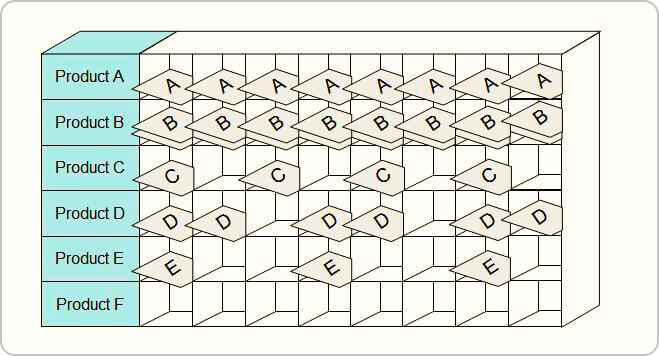

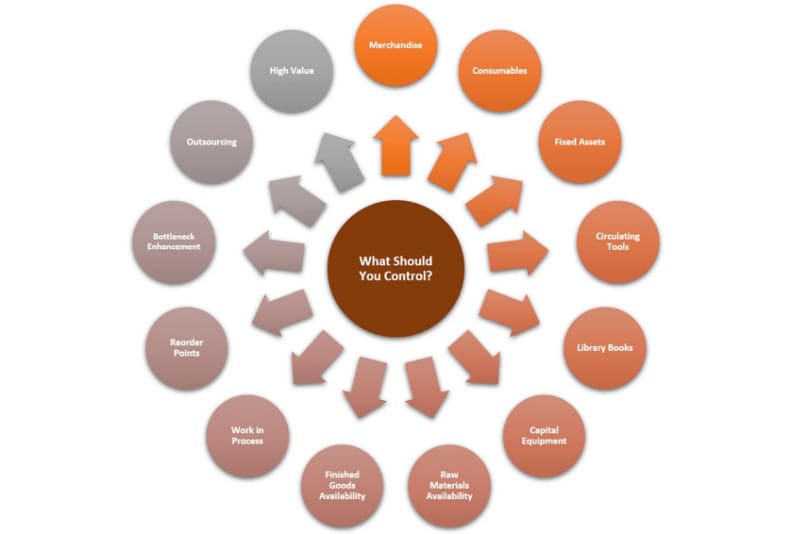

The level capacity strategy, the focus is on the process where product output remains at a somewhat fixed level and increases/decreases in demand are satisfied through strategic decisions of utilizing inventory (maintain buffer stock), outsourcing and backorders In comparison to level capacity strategy is adjusting capacity to follow How to increase your company's bonding capacity There are four primary ways for contractors to boost their bonding capacity 1 Provide proper financial statements and reports Work with a construction CPA so you know which reports the surety will be looking at, and make sure they are presented professionally 2 Product Capacity Planning Product capacity planning ensures that you always have enough raw materials and products needed to complete an order Raw material management is key to product capacity planning, and multi level bill of materials (BOM) are especially important if your products require a lot of product variants and subassemblies

Capacity Planning What Is It And How Do I Implement It Projectmanager Com

Production Management Definition Importance And Software Solutions

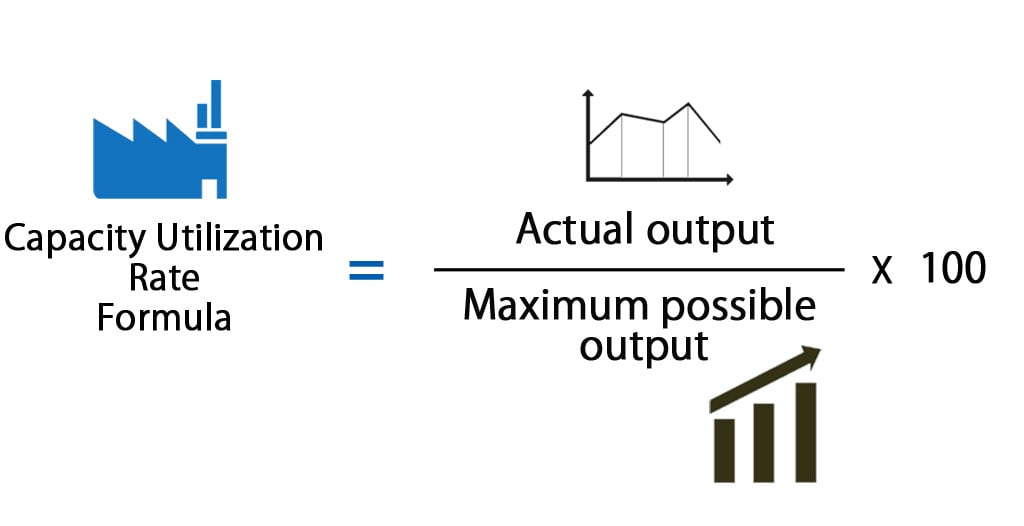

32 Example RoughCut Capacity Planning Texprint Company makes a line of computer printers on a producetostock basis for other computer manufacturers Each printer requires an average of 24 laborhours The plant uses a backlog of orders to allow a levelcapacity aggregate plan This plan provides a weekly capacity of 5,000 labor hours 1 Product capacity planning Product capacity planning ensures you have enough products or ingredients for your deliverables For a florist, this would be flowers, vases, and cards For a pool maintenance company, this would be things like chlorine that are required to The formula for calculating capacity utilization is Capacity Utilization = (Actual level of output / maximum level of output) * 100 Examples of capacity utilization Suppose AB Company manufactures 10,000 units at 10 dollars each and wants to increase its capacity to ,000 units The capacity utilization rate is

Researchportal Port Ac Uk Portal Files Boydell 11 Pub Ch7 Capacity Planning And Management Pdf

Q Tbn And9gcrs Vbjfk Wklku00oppxm 5a Bh0apj0ph4j6lyirzovthyxxs Usqp Cau

Company is in a position to use its production capacity to the fullestFor example, the capacity of a firm is to either produce 100 microwaves or 75 refrigerators This is less confusing than just saying the capacity is 100 or 75 Another method of measuring capacity is by referring to the availability of inputs This is usually more helpful if How To Write an Entry Level Resume Objective (With Examples) If you are a student looking for a position in your chosen field or a more experienced professional who is seeking a change of career, you are most likely applying for entrylevel jobs

What Is Corporate Level Strategy Definition Salient Features And Classification Business Jargons

What Is Organizational Development A Complete Guide Aihr Digital

For example, there could be a scenario where demand is more than production capacity; Resume Objective Examples for a Sales Resume To offer my skills to your company, especially in the field of (sales), (advertising), and (analytics) to grasp the power to enhance my professional skill set in accordance with organizational objectives Acquire a job as a (Sales Associate) with (Company Name) to use developed (people) skills Hence, for a system working at full capacity, it is the average quantity produced in a given time period If your system is working at less than capacity, however, you cannot take the total production quantity For example, if you produced ,000 gizmos per week, but half of the time your people were idling, then you cannot use the ,000

First And Second Shift Capacity Cost To Raise Chegg Com

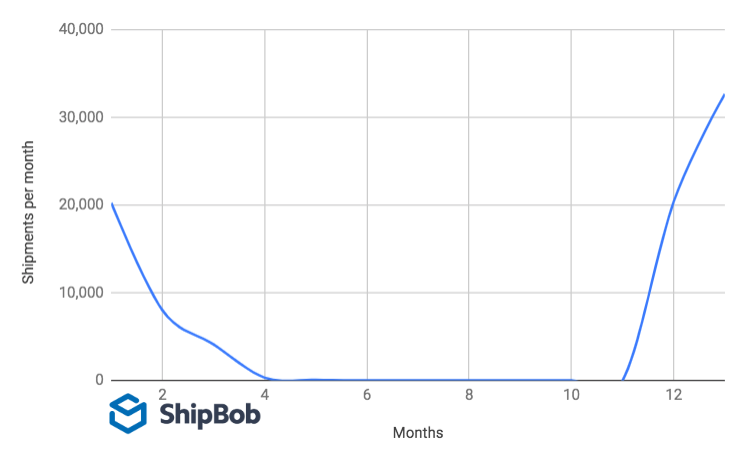

Coronavirus S Impact On Supply Chain Mckinsey

It depends on how a company handles the productionvolume variance in the endofperiod financial statements For example, if the adjusted allocationrate approach is used, each denominatorlevel capacity concept will give the same financial statement numbers at yearend 3 Examples of Production Capacity John Spacey, Production capacity is the volume of products or services that can be delivered by the operational resources of an organization Resources include factors such as land, labor, facilities, infrastructure and machines The following are illustrative examples of production capacityFunctional level strategies will be specific and will apply to a variety of functional areas (departments) For example, building on the diversification example, the functional level strategies that support that business level strategy might be R&D Redesign product Marketing Implement new advertising plan

Ansoff Matrix Explained With Examples B2u Business To You Com

Assessing Sustainability In Global And Regional Partnership Programs

This A level Business revision tutorial investigates the concept of capacity utilisation in a business and the strategies managers may use if capacity utilisIn this situation, a company needs to fulfill its requirement by buying from outside If demand is equal to production capacity; Business capacity is the volume of work that can be handled by an organization, team, process, service or tool It can often be scaled up and down by adding, reallocating and subtracting resources The following are illustrative examples of a business capacity

1

Roadmap Scaled Agile Framework

Capacity planning is a strategic process whereby a company determines what level of capacity it will need to satisfy the level of demand for its products or services over a period of time ThreeAn example of level capacity management could be the first step of the production of salt by evaporation (in Italy there is one industry like this in Salina)For a service business, you need to evaluate equipment and personnel needed to deliver your service in the way your strategy calls for To give an example, if your strategy is to capture market share by offering volume discounts, you must have the capacity to make more products, buy more products or hire more service personnel

Capacity Utilization Definition Example And Economic Significance

A Full Exhaustive Balanced Scorecard Example Clearpoint Strategy

Guidelines for assessing capacity, as set out in Model Rule 114 and the comments to the rule Standards of capacity for specific legal transactions The law generally presumes that adults have capacity unless they have been adjudicated as incapacitated, for example, through guardianship or conservatorshipHolidays, for example 5 Normal capacity is the level of capacity utilization that satisfies average customer demand over a period of time—often two to three years 6 Masterbudget capacity utilization is the level of capacity that managers expect for Capacity planning is the process of determining the production capacity needed by an organization to meet changing demand for its products 3 Capacity is the rate of productive capability of a facility Capacity is usually expressed as volume of output per time period

Operations Strategy With Examples Studiousguy

The Company For Which You Work Recently Implemented Time Driven Activity Based Costing Tdabc In Conjunction With Its Enterprise Resource Planning Erp System Management Is Pleased With The Homeworklib

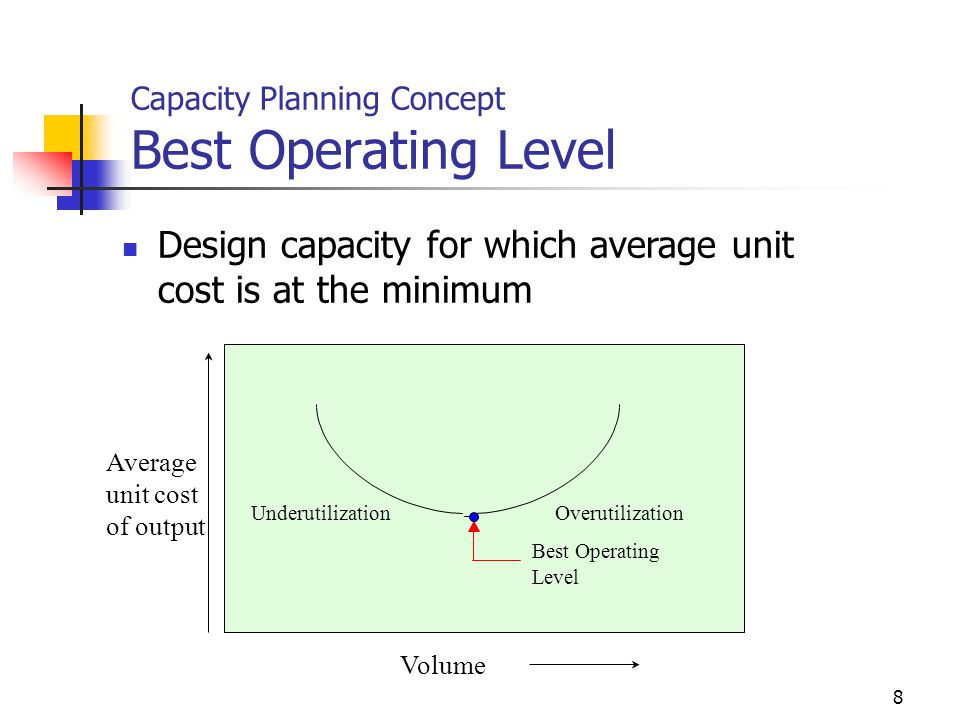

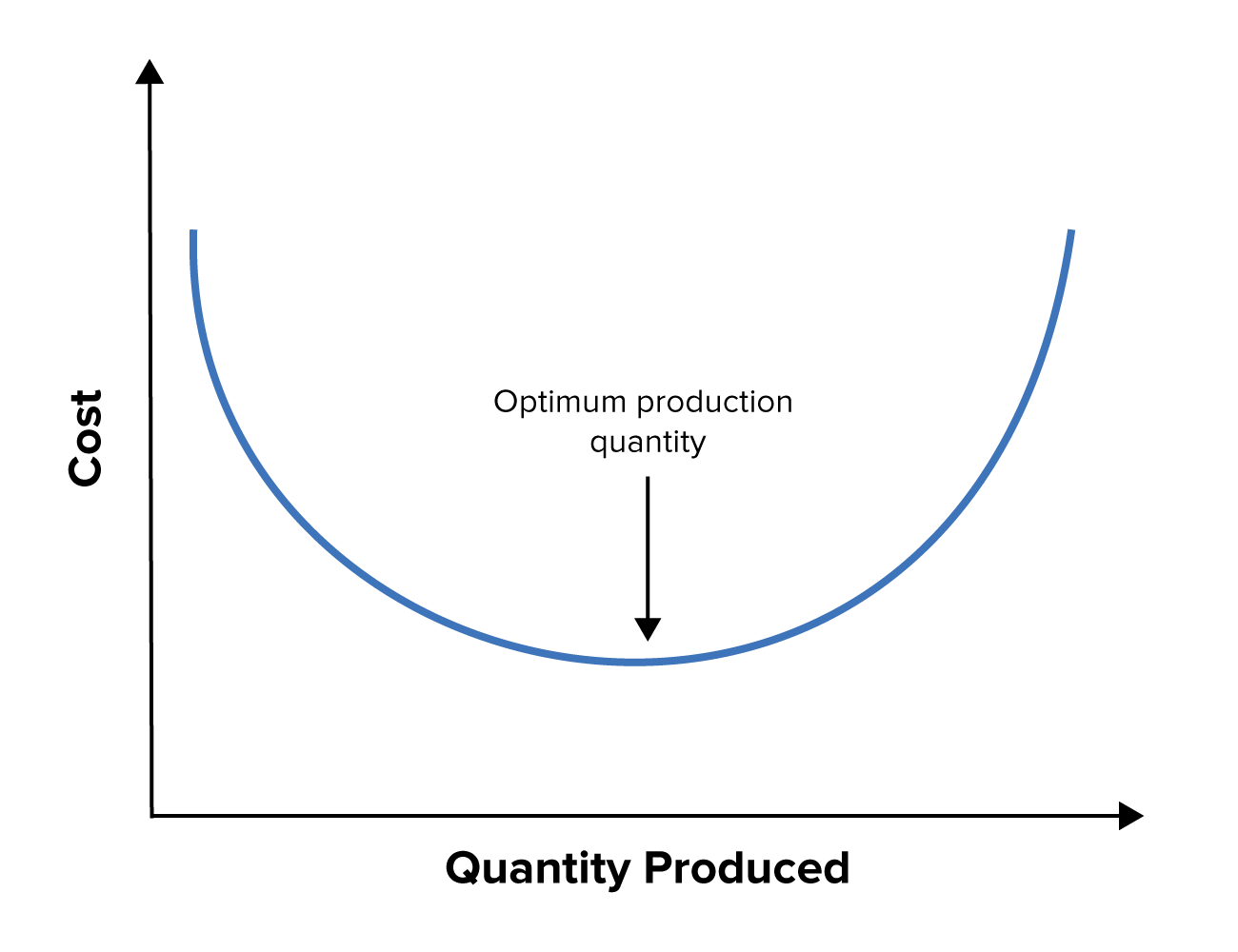

Capacity Planning It's pprove/cancel projectsOptimum capacity is a manufacturing rate with the lowest possible cost When a company is at optimum capacity, it produces the most it can with the smallest amount of cost In other words, a production capacity in which the cost of production of one extra unit is the same as the average cost for every unit Capacity costs are expenditures made to provide a certain volume of goods or services to customers For example, a company may operate a production line on three shifts in order to provide goods to its customers in a timely manner Each successive shift constitutes an incremental capacity cost

Aggregate Planning Strategy Organization Levels System Examples Model Type Company System

First Shift Capacity First And Second Shift Capacity Chegg Com

This revision video provides an overview of the concept of capacity, capacity utilisation and some of the issues facing businesses operating at low or high uActivity Capacity The degree to which a particular action is expected to perform Activity capacity refers to an activity's upper threshold of performance based on historical results and futureCapacity Constraint Company Policies Amount of product subcontracted and backordered Size of work force Capacity Level of labor skill required Low High Job discretion Low High Example Problem Forecast Units

Coronavirus S Impact On Supply Chain Mckinsey

/IncomeStatementFinalJPEG-5c8ff20446e0fb000146adb1.jpg)

Income Statement Definition

Excess Capacity Overview Causes And How To Monetize It

Capacity Utilization Rate Definition Formula How To Calculate

Our Initiative To Reduce Emissions On Ncs And Meet The Target Of 50 Reduction In 30 Explocrowd

Master Production Schedule

Internal And External Environment Factors That Influences Organizational Decision Making

What Is Capacity Planning Examples Types Optimoroute

What Is Capacity Planning Examples Types Optimoroute

Strategic Capacity Planning Aggregate Planning Ppt Video Online Download

4 Steps To Strategic Human Resource Planning Lucidchart

Common Types Of Corporate Strategies Boundless Management

11 Capacity Planning And Control Operations Management

Understanding Organizational Structures

Capacity Planning Meaning Classification And Its Goals

Solved Excess Capacity Williamson Industries Has 7 Billion In Sales And 2 8 Billion In Fixed Assets Currently The Company S Fixed Assets Are Op Course Hero

Erp Examples Examples Of Erp Systems For 21

What Is Capacity Planning Examples Types Optimoroute

Aggregate Planning Strategy Organization Levels System Examples Model Type Company System

Diseconomies Of Scale Definition 8 Types And 5 Examples Boycewire

Capacity Building Wikipedia

Supply Chain Management Wikipedia

Capacity Management

What Is Heijunka

The 21 Guide To Product Roadmaps

Entry Level Sales Resume Examples Template 10 Writing Tips

Entry Level Accounting Resume Example Accountant Resume Resume Objective Entry Level Resume

Solved Problem 3 19 Full Capacity Sales The Discussion Of Chegg Com

Ability Capability Capacity And Competence Bpi The Destination For Everything Process Related

Capacity Planning Types Lead Lag Average Strategies Video Lesson Transcript Study Com

9 Business Roadmap Examples For Scaling Your Organization

Capacity Planning Organization System Examples Definition System Long Term Capacity Planning

Focus Improvement On The Manufacturing Constraint Lean Production

Process Design Capacity Planning Roy D Shapiro Core

Operations Strategy With Examples Studiousguy

Capacity Planning What Is It And How Do I Implement It Projectmanager Com

Coronavirus S Impact On Supply Chain Mckinsey

Will The Financial Statements Of A Company Always Differ When Different Choices At The Start Of The Accounting Period Are Made Regarding The Denominator

Strategy Under Uncertainty

Strategic Capacity Planning Aggregate Planning Ppt Video Online Download

What Is S Op Sales And Operations Planning Explained Anaplan

Production Capacity Definition Importance Example Operations Supply Chain Dictionary Mba Skool Study Learn Share

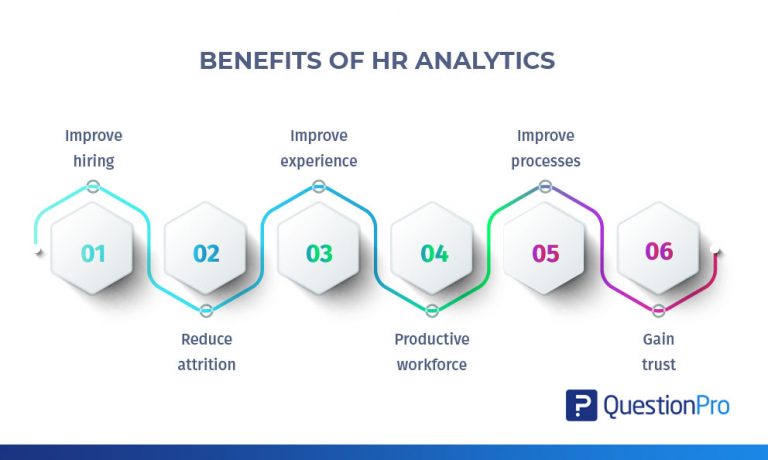

Hr Analytics Definition Example Hr Metrics Dashboard And Predictive Hr Analytics

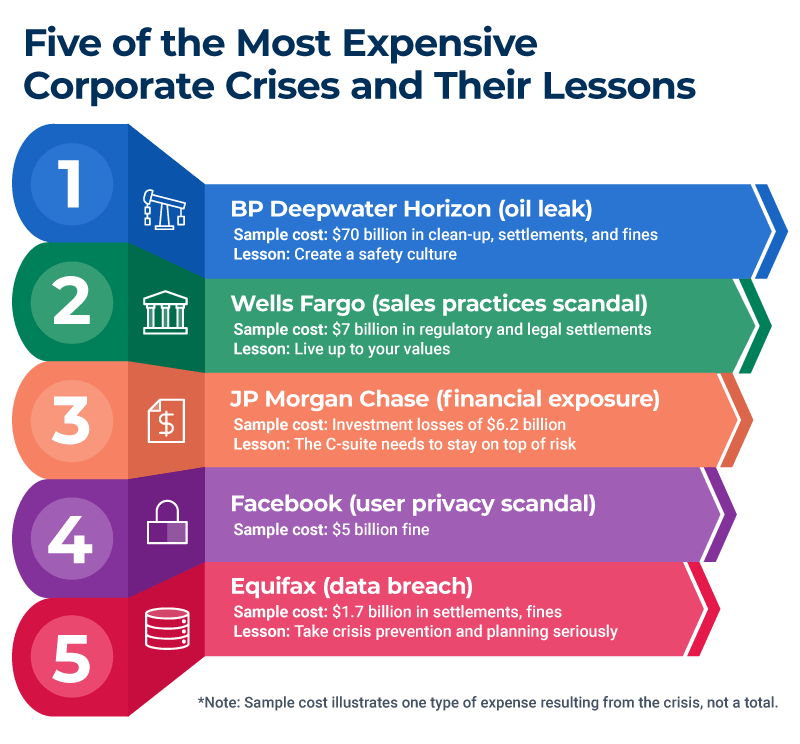

The Best Crisis Management Examples Smartsheet

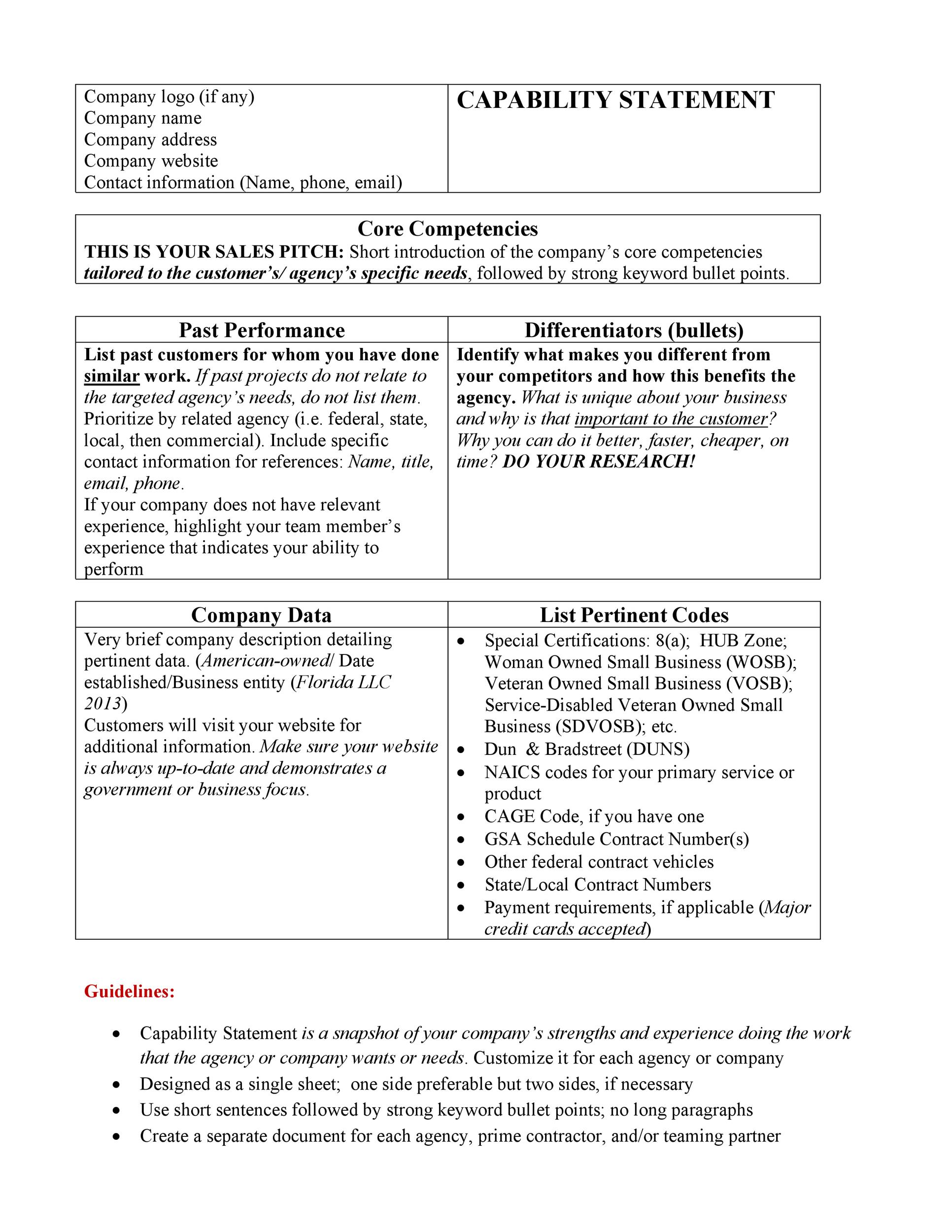

39 Effective Capability Statement Templates Examples ᐅ Templatelab

Solved Capacity Analysis Capacity Analysis Being Able To Chegg Com

/diseconomies_of_scale_final-db85c494049d42aca10deb37e214a013.png)

Diseconomies Of Scale Definition

Demand Forecasting How To Forecast Demand Examples

Capacity Utilization Rate Formula Calculator Excel Template

Found Under Automation Next Round Industry Total Chegg Com

Strategic Capacity Planning Capacity Utilization

1

Guide To Gap Analysis With Examples Smartsheet

Porter S Generic Competitive Strategies

Aggregate Planning Strategy Organization Levels System Examples Model Type Company System

Capacity Planning What Is It And How Do I Implement It Projectmanager Com

1

Sales Objectives Examples Pipedrive

What Is Organizational Development A Complete Guide Aihr Digital

Solved Please Help With The Last Four Red Numbers In The

Demand Forecasting Meaning Importance Examples With Questions

A Complete Guide To Product Roadmaps With Examples Aha

Mustafaaltawashy Files Wordpress Com 13 06 Inventory Horn Essayscan0001 Pdf

What Is Capacity Planning Examples Types Optimoroute

Everything About Capacity Planning Strategies Its Benefits

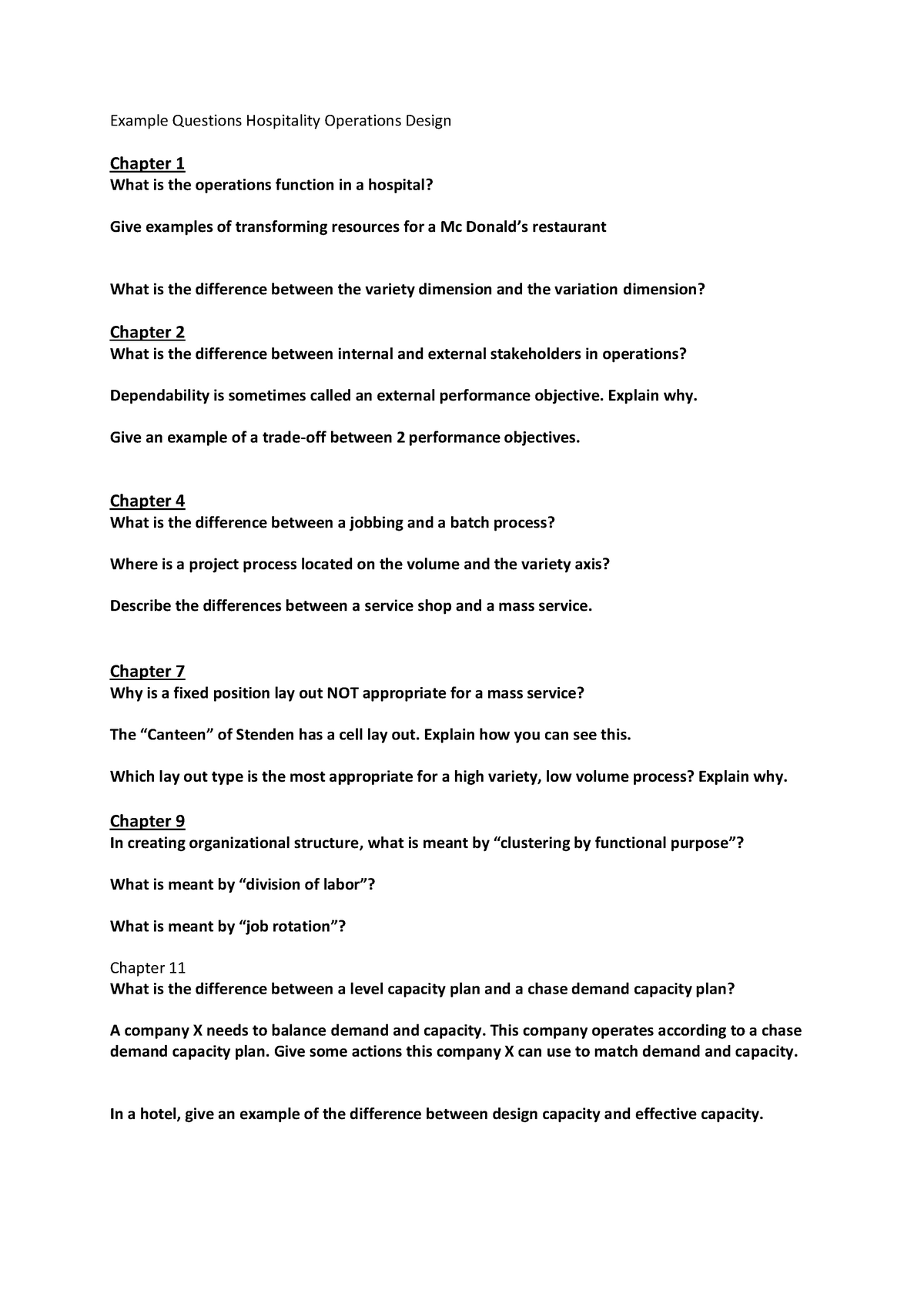

Proef Oefen Tentamen 9 Oktober 14 Vragen Hoorcollege Studocu

Capacity Utilization Rate Formula Calculator Excel Template

Capacity Utilization Rate Formula Calculator Excel Template

Pause Proceed With Caution Strategy Stability Strategies Corpora

Lecture 5 Master Product Scheduling Books Introduction To Materials Management Sixth Edition J R Tony Arnold P E Cfpim Cirm Fleming College Emeritus Ppt Download

56 Strategic Objective Examples For Your Company To Copy Clearpoint Strategy

Inventory Control Best Practices And Everything You Need Netsuite

4 Steps To Strategic Human Resource Planning Lucidchart

How Is Yield Management Implemented In Airline Industry Ayat Saleh

Achieving Economies Of Scale Strategy Tools From Mindtools Com

How To Create A Sales Plan Template Examples

Digital Transformation Online Guide To Digital Transformation

9 Business Roadmap Examples For Scaling Your Organization

Business Operations Overview Examples How To Improve

Itil Capacity Management Bmc Software Blogs

Capacity Utilization Definition Example And Economic Significance

Researchportal Port Ac Uk Portal Files Boydell 11 Pub Ch7 Capacity Planning And Management Pdf

Strategy Under Uncertainty

/investopedia5cscredit-5c8ffbb846e0fb00016ee129.jpg)

Five Cs Of Credit Definition

No comments:

Post a Comment